Search This Supplers Products:saw bladereciprocating saw bladesmetal cutting bladediamond bladeshole sawdrill bit

- Home

- About us

- Products

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

- Faqs

- News

- Certificate

- Contact us

Are the puzzle blades interchangeable?

time2022/04/30

- Jigsaws are versatile tools for cutting precise and safe lines and should be a must-have in any toolbox. However, you may have different jobs that require installing various blades for your puzzle, which in the past can be confusing and difficult to manage and keep track of. Fortunately, the new blade technology takes the guesswork out of using different types of blades on various puzzle machines.

Jigsaws are versatile tools for cutting precise and safe lines and should be a must-have in any toolbox. However, you may have different jobs that require installing various blades for your puzzle, which in the past can be confusing and difficult to manage and keep track of. Fortunately, the new blade technology takes the guesswork out of using different types of blades on various puzzle machines.

Jigsaw blades are interchangeable, as most models of jigsaws are compatible with T-blade heads. The T-shaped head of the puzzle can be attached to the puzzle without tools. It is interchangeable with almost all newer designs of the puzzle, which is why most newer models use this interchangeable blade fastening design.

There are many different puzzle brands and blades out there. However, most popular brands can handle older U-blade designs (which require a tool to attach to the puzzle) or tool-less T-blade.

There is also a U-shaped blade for older models and some newer models that accept both blade types.

Which puzzle blades are interchangeable?

Of the two types of puzzle blades available, the T-blade is the more common type of attachment for modern puzzles, making it more likely to be interchangeable between puzzle brands.

U-shaped blade heads for puzzles are also called "universal blades," which is confusing because not many modern puzzles use this type of blade head attachment.

Basically, all the major modern jigsaw brands are switching to T-shank blades because it makes changing blades on the machine faster and easier.

Don't be fooled, even if U-shank blades are called the "all-purpose" blade type. U-shanks are outdated, while T-shank blades are more easily interchangeable with other brands of jigsaws due to their popularity.

U-shaped puzzle blade

On older models of puzzle machines and some of the less expensive models available today, the U-shaped blade head can be attached to the puzzle machine with a screw set. The extra tools needed to secure the blade to the saw can be annoying.

This is a big reason why most mainstream puzzle makers no longer use U-shaped heads for their puzzle blades.

Although the U-shank blade is nicknamed the "universal" blade, that's no longer true for modern jigsaws.

The U-shaped tip or handle gets its name from the U-shaped cut in the tip. There needs to be a hole just below the U shape and the screw set is secured with a tool.

This extra step of securing the blade to the puzzle can be annoying and take longer to replace.

Although it has lost its popularity among modern puzzle makers, blade handles and puzzles using them are still available. (Source: notified features)

T-shaped puzzle blade

The most widely used shank type for jigsaw blades is the T-shank. The T-handle on the jigsaw blade is very popular because it fastens to the jigsaw without any tools.

Almost all contemporary models and brands of jigsaws use T-shank blades or U- and T-shapes.

Many of the most traditional puzzles available today have a design with a T-shaped blade handle because they are easy for consumers to use.

The T-shaped shank design is called a "T" due to the shape of the shank head at the top of the blade.

Removing or inserting the blade into the puzzle can be secured to the puzzle at the touch of a button.

Since no tools are required to secure the blade handle to the jigsaw, many manufacturers have switched from U-shaped to T-shaped handle blade heads, making the T-shaped interchangeable with many models of saws

How to choose the right puzzle blade

Choosing the right jigsaw blade requires you to understand how several key features of the jigsaw blade interact with the material you are cutting.

Once you've determined that your puzzle blades are interchangeable and used with your puzzle, there are several factors you should consider before purchasing blades for your puzzle.

Some of the most important factors to consider for jigsaw blades are detailed below:

Teeth per inch (TPI)

The number of teeth per inch on the blade affects the speed of the cut and determines the final balance and speed at which the wood enters the cut.

Cutting with tight angles and precision requires more teeth on the blade, and a good rule to keep in mind is to always keep at least three teeth in the wood.

The fewer teeth per inch, the faster and less accurate the cut. Use a higher numbered TPI on smaller pieces of wood or materials for complex jobs, and use a lower TPI blade on larger materials that require more power and speed. (Source: KMS Tools)

blade metal

Not all blades are made of the same material. Some metals are superior to others for precise cutting and durability.

Several blade material types can cut some materials, and some can cut a variety of materials.

The three main metal types for making jigsaw blades are listed below, along with details on the types of jobs they are best suited for:

High Carbon Steel (HCS): HCS is an excellent metal for blades cutting wood and plastic. Since they are not as stable as other types of metal jigsaw blades, they tend to dull faster. HCS is more flexible than other blade types and is ideal for rolling cuts.

High Speed Steel (HSS): HSS metal inserts are more durable than the more common and cheaper HCS inserts. HSS metal blades are ideal for cutting non-porous materials such as metal or acrylic. However, HSS is not as flexible as HCS inserts and is more prone to breakage.

Bi-Metallic (BIM): Flexible and durable, BIM blades are the best metal blade type for all jigsaw cutting projects. However, BIM blades are more expensive than HCS and HSS blades.

Tooth direction

Most cuts are done on the upstroke of the puzzle, as this is the natural movement to maintain forward momentum through the cut. Most jigsaw blades are designed for precise cuts using an up-stroke design with teeth that slope up on the shank.

However, if you need a specialized blade for a specific material or unique design, you may want to consider a blade that slopes down, away from the handle, cutting on the downstroke.

These downcut blade types are available, although they are not as common as upcut blades.

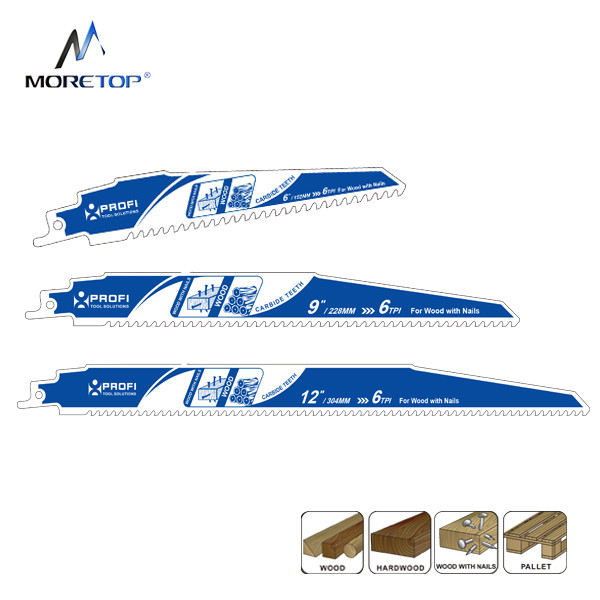

Unique UV printing to show clear cutting instruction.

Unique UV printing to show clear cutting instruction.