Search This Supplers Products:saw bladereciprocating saw bladesmetal cutting bladediamond bladeshole sawdrill bit

- Home

- About us

- Products

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

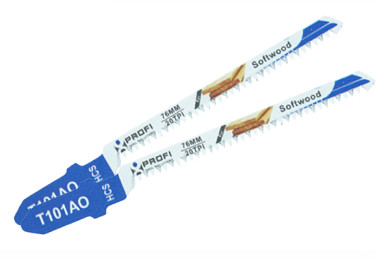

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

- Faqs

- News

- Certificate

- Contact us

Reciprocating Saw tutorial: Basics, operations and applications

time2022/05/28

- The way to reduce tiles

Porcelain is a completely fragile material that cracks or shatters without problems because of its molecular structure. We want to be very cautious when keeping it, because placing it down will smash it.

Reciprocating Saw tutorial: Basics, operations and applications

What is a reciprocating saw

They're called Reciprocating saws because the blades move like handsaws and are cut by Reciprocating. All you have to do is hold a reciprocating saw, place the blade on the object to be cut, and pull the trigger to cut. The end of the reciprocating saw blade has a small hole, which is used to hold the saw blade in place. Because the fixed saw blade has only one point, it is unstable at high speed. Therefore, the reciprocating saw is only suitable for cutting objects, and does not require a precise cut. In this article, you will learn the basic knowledge of reciprocating saws, basic use methods and application scope, and finally I will introduce some safety considerations. If you prefer to watch the video, just hit the Play button.

Type of reciprocating saw

Battery vs wired

Battery-powered reciprocating saws are popular because they're so easy to use that you don't have to hunt around for power while you're working. If the work is light, a battery will suffice. However, the battery version of the reciprocating saw because of this advantage, resulting in a lack of power has become its disadvantage. First, if you're cutting a lot of thick stuff, like 2×10 (1.5inx9.25in) planks, the battery version of the reciprocating saw can be very taxing. Of course, if you just cut a few plastic tubes, thin boards, twigs, etc., the battery version is fine. Also, if you have a lot of demolition work to do, battery life is an issue for the battery version, so it's not a good fit unless you have multiple high-capacity batteries to replace.

The wire version on the top and the battery version on the bottom

I use the wired version of the reciprocating saw most often, and it has enough power to cut through thick wood or metal. The downside: every time you use it, no matter how big or small you work, you need to find a power source. Power is easy to find in some places, but not so lucky in others. Of course, if you're just doing DIY at home, the wired version of the reciprocating saw doesn't have a problem finding a power source.

If you are considering buying a reciprocating saw, I have some suggestions for you. In cases where you have a major project to do, such as redecorating the bathroom, or have a lot of demolition work to do, I recommend getting the wired version. Of course, if you're going to be a professional decorator, you definitely want the wired version. If you don't currently have an upcoming project, and your primary use is for home maintenance and simple DIY renovations, I recommend buying a battery-powered reciprocating saw that matches the brand of your other tools.

Regular vs. small

Most reciprocating saws are conventionally sized, two-handed, and fully powered. The wired version and the panel reciprocating saw above are the regular ones. In recent years, smaller versions of the reciprocating saw have also been favored by certain types of workers. They are small, light and can be operated with one hand. For example, the plumber and electrician work, in the case of limited space, people can not enter, with a small reciprocating saw, can be cut with one hand. Small reciprocating saw power is smaller, can only cut some plastic, metal thin tube and some thin wood, etc.. In most cases, DIY at home doesn't have such tricky cutting positions, so I think you should just buy a regular size reciprocating saw.

Small reciprocating saw

Brand difference

The origin of the reciprocating saw is the Milwaukee Sawzall. After years of improvement, the Milwaukee reciprocating saw is considered the best choice. It was heavy, heavy in the hand. Cutting is very stable, the vibration range is very small, long time to use the hand will not numb. It has enough motivation to do all the work it's given. Although other brands of reciprocating saws are not as comprehensive as Mvoch's, they all get the job done and you can choose according to your own needs.

How to choose a saw blade

Let's talk about the blade of the reciprocating saw. The blades of the reciprocating saw have different lengths and widths, and their saw teeth have different styles, but they all have one thing in common, that is, they all have this fixed slot at the end of the saw blade, and the fixed slot is inserted in the position of the clamping blade at the front of the reciprocating saw.

Choose the right saw blade for your needs. Saw wood to choose a large saw blade; For metal sawing, choose a saw blade with dense serrations. If you're going to cut drywall, look for a saw blade with a big edge, which will cut faster and wear less. If you are cutting stone, such as tile or natural marble, you need this saw blade with diamond abrasive. Large saw blades are mostly bi-metal, which is the main wood for sawing, but also allows some iron in the wood, such as nails and iron blades. This is more convenient when dismantling, do not need to worry about hitting the nail saw blade, can directly cut the nail.

Saw blades are used from top to bottom: wood and metal, wood and metal, cast iron, metal

The use of reciprocating saws

Basic operation method

In general, hold the end handle of the reciprocating saw with your dominant hand, place your index finger on the trigger of the switch, and hold the front rest with your non-dominant hand. The trigger of most reciprocating saws is pressure-sensitive, meaning that if you exert less force, it will run slower. With greater force, it increases its speed until it runs at full speed. Reciprocating saws generally have six speeds, depending on your job needs to pull the trigger force. Some reciprocating saws have knobs to adjust speed, such as when the knob is set to third gear, and you can push the trigger all the way to third gear.

Grip the reciprocating saw with both hands

If you are dismantling, it is best to cut slowly, because reciprocating saws are fast and destructive, and if you cut at full speed you may damage the pipeline hidden behind the wall. If you cut metal, the blade tends to bounce at first, causing unwanted scratches on the metal. Start at a low speed, when the blade has formed a shallow trench in the metal surface, and then cut at a higher speed, the blade will not bounce. The reciprocating saw is different from other saws in that the blade can be placed directly on the object to be cut, and then the trigger can be pulled to start cutting, instead of waiting for the reciprocating saw to run at full speed. Other rotary cutting tools such as circular saws often require the saw blade to operate at full speed before cutting safely.

Replace the saw blade

Replace saw blade must remove power supply first!! The shank of a fixed saw blade can be moved back and forth. When the blade of the reciprocating saw is not fully extended, you need to pinch the blade and pull out the blade before replacing the blade. The head of the blade is where the saw blade is held. Turn it 90 degrees counterclockwise (or clockwise), and the middle slot of the blade head will come loose. Insert the perforated end of the saw blade into the slot of the cutter shank, then release it, the holder springs back to its original position, and the saw blade is installed. To remove the saw blade, turn the head of the blade shaft counterclockwise (or clockwise) 90 degrees, and then pull out the saw blade.

A device for fixing saw blades

The saw blade installation is not required. The saw blade can be mounted downward or upward. Choose the orientation of the installation according to your needs.

Method of replacing saw blade

Guide the function of boots

The guide boot is a metal device at the front end of the reciprocating saw. The blade runs through the middle of the guide boot. The first function of the guide boot is to provide stability. If you do not use a guide boot against the object you are cutting, the reciprocating saw will shake so much that it will not be able to complete the cutting. Second, adjust the Angle of the boot according to the shape of the object you are cutting and your position. Reduce the Angle between the boot and the saw blade if you are cutting small objects. Increase the Angle between the boot and the saw blade if you are cutting large objects.

Guide boots have a maximum movement range, do not exceed the maximum mark (Max)

Another function is that the guide boot can be adjusted position. The shortest position of the guide boot is close to the reciprocating saw, where the saw blade is longest. When the boot elongation, it will shorten the length of the saw blade, suitable for small space, short distance cutting. Because changing the position of the guide shoe will change the cutting position of the saw blade accordingly, we can take advantage of this point to make full use of the saw blade. For example, if the base of the saw blade is blunt, but the other part is still sharp, we can extend the guide boot and use the middle of the saw blade to cut.

Guide boots can change the cutting position of the saw blade

Track mode vs. straight mode

You may have noticed that on some reciprocating saws there is a setting: Orbital Mode or Straight Mode, each of which has its own specific purpose.

Switch button between track mode and straight mode

The two modes of the reciprocating saw refer to the motion of the blade. Straight line mode refers to the saw blade straight in and out of the cutting, suitable for cutting metal and other hard materials. Track mode, on the other hand, creates a slight circular motion in and out of the blade, which cuts softer material faster and helps remove debris from the blade's path more quickly.

Using straight line mode:

Cut plastic, such as PVC

Cut metal, like wire guides

Wood needs to be cut with precision

Use of track mode:

Wood with nails

Cut mixed materials, such as removal

Wood that doesn't require precision cutting

Application of reciprocating saws

Reciprocating saws are most commonly used in the demolition process of house decoration. Reciprocating saws are the best choice for wall, frame, PVC bathtub, pipeline and floor. Change door window is its specialty more, it can dismantle old door frame, window frame easily. The advantage of reciprocating saws in applications is that they cut fast, can work continuously for a long time, are very durable, and the blades are cheap.

When the reciprocating saw is used to dismantle the wooden structure, it can easily cut off everything you want to cut off, improve work efficiency, save energy and time. For example, removing the frames of houses, wooden balconies and wooden fences, where there are lots of nails and screws in the wooden structure, is much easier with a reciprocating saw than with a crowbar. Just remember to have some extra saw blades.

Reciprocating saws can also trim trees and even cut trunks. A reciprocating saw is a great way to remove dry branches that can fall and hurt at any time. Reciprocating saws can even be used to remove tree roots. When you have large stumps to remove, use a plane to loosen the soil around the roots. When the roots are exposed, use a reciprocating saw to cut through the roots.

It is worth noting that the reciprocating sawing is used to cut all kinds of pipes, such as PVC pipes, wire conduits, iron pipes and so on. When cutting the pipe, the pipe will slip, so it is necessary to fix the pipe with clamps before cutting.

Finally, the reciprocating saw can also be used to open holes. A special application of the reciprocating saw is to cut directly into a flat surface without having to make an opening beforehand. This method is generally used when opening a hole in the wall for repair, adding a fan, or opening a hole in the ground. The method is to attach the reciprocating saw to the wall of the hole, parallel to it. Then with the guide boot as the fulcrum, with the guide boot against the position of the hole to be cut, and then slightly lift the handle of the reciprocating saw, increase the Angle of the reciprocating saw with the wall. At this point, the tip of the saw blade just touches the plane to be cut. Gently pull the trigger, slowly cut, slowly increase the Angle of the reciprocating saw to the wall, until it is gradually cut, can increase speed.

Matters needing attention

Be sure to disconnect the power supply when replacing the saw blade

The wide range of motion of the saw blade ensures that there are no pipes behind the object being cut

Essential safety equipment: safety glasses, hearing protection, breathing filter

Grip the reciprocating saw with both hands to counter the rebound

The saw blade is easy to deform. Check the saw blade regularly and replace it in time

A fresh saw blade is very hot. Do not touch it with your hands immediately

Moretop plunge saw blades are specially designed for different plunge saws like Festool, Dewalt, Bosch, Mafell.

moretop vacuum brazed diamond blades, Vacuum brazing technology could attach large pieces of diamond grit to the cutting edge.