Search This Supplers Products:saw bladereciprocating saw bladesmetal cutting bladediamond bladeshole sawdrill bit

- Home

- About us

- Products

- SAW BLADES

- DIAMOND BLADE

- RECIP BLADES

- JIGSAW BLADES

- OSCILLATING MULTITOOL BLADES

- HACKSAW BLADES

- HOLESAWS

- WOOD DRILL BITS

- MASONRY DRILL BITS

- METAL DRILL BITS

- SPECIALITY DRILL BITS

- ABRASIVE DISCS

- WIRE BRUSHES

- FLAP DISCS

- SANDING PRODUCTS

- IMPACT TOOL ACCESSORIES

- X-LOCK ACCESSORIES

- DRILL BIT SETS

- WORKTOP JIGS

- DIAMOND STONE

- CANVAS BAGS

- HAND TOOLS

- Faqs

- News

- Certificate

- Contact us

What's a hollow saw?

time2022/08/12

- A hollow noticed is a cylindrical noticed blade attachment designed for use at the side of an electric powered drill to reduce perfectly round holes. They're very popular within the electrical and plumbing industries and are extra effective than flat and twist bits in programs that require drilling large, deep holes or enlarging current holes.

A hollow noticed is a cylindrical noticed blade attachment designed for use at the side of an electric powered drill to reduce perfectly round holes. They're very popular within the electrical and plumbing industries and are extra effective than flat and twist bits in programs that require drilling large, deep holes or enlarging current holes.

In this Toolstop guide, we give an explanation for the whole thing you need to recognise about hollow saws, how to use them, and which applications they may be fine perfect for.

Hollow saw explain

A hollow noticed is capable of reducing holes a lot large in diameter than a wellknown drill bit. They shape a hollow within the workpiece without reducing through the center fabric.

The hollow saw attaches in your drill through a mandrel used to clamp other shifting device additives. The mandrel can convey a drill bit, so you can make a guide hole in the material to reduce strolling earlier than cutting. At the same time as convenient, this isn't always important, and now not all hollow saws require one.

Because hole saws reduce most effective the fringe of the material and now not the core cloth itself, they're regularly preferred for making large holes. The identical hole can be drilled faster and with less power than the use of a fashionable or flat bit.

Hole saws come in a ramification of sizes and diameters and may be used to cut a variety of substances. Whilst shopping a hole noticed or hole noticed kit, it's far vital to take into account the material to be reduce and the required end. The diameter that a hollow saw can cut is determined by way of the diameter of the hole noticed itself, and the intensity that it may reduce is determined through the running period. Some may come with a detachable mandrel, a few with a hard and fast mandrel, and some never. In this case, you need to purchase one separately. Fortunately, at Toolstop, we have a massive selection of hollow saws, mandrels, and hole saw kits.

Bosch hole noticed

Part of a hole saw

A hollow saw consists of reducing enamel, grooves, and on occasion a manual drill and mandrel (as described above).

The teeth may have variable or consistent pitch and will normally be set at a 60° angle to effortlessly reduce material. Variable pitch is the change inside the distance between enamel. This gives a smoother reduce while decreasing blade wear. Regular spacing way that the gap among those two points stays steady. They cut a bit slower than variable pitch, but they reduce extra finely.

Hollow saws may be ready with exclusive TPI (enamel per inch). The higher the TPI, the slower the cut, but the smoother the finish. The lower the TPI, the faster the cut, however the smoothness can be reduced.

Be aware that the higher the TPI, the less likely the hollow noticed is to rip the piece. The decrease the TPI, the much more likely that is to show up. We typically recommend 1-4 tooth in step with inch equals low TPI, even as 10 teeth according to inch equals high TPI.

You'll notice that every hollow incorporates slots on its facet. Their reason is to permit particles and dust to break out.

Part of the hollow

The way to Use Holes

Hole saws may be used in lots of programs. Usually consists of, but is not constrained to, putting in drains and drilling holes for pipes and wiring.

As soon as you have determined the scale of the hole you want to reduce and selected a hollow saw that fits the fabric you are cutting, the use of one is honestly quite simple. Comply with these steps:

Insert the mandrel thru the back of the hole noticed

Screw the hollow saw onto the mandrel threads till fixed

Insert mandrel into drill chuck and tighten until securely secured

In case your mandrel does no longer have a manual bit, you could need to drill your own guide hollow (although this isn't required)

Noticed your hollow to the area in which you need to reduce

Begin through drilling slowly and gradually growing the speed of the bit

Every so often again hole noticed out the hole to take away dust

As soon as the required hollow has been successfully drilled, get rid of the waste material from the hole noticed

It surely is that simple. Note that it's far important to always ensure which you are slicing with a well powerful drill hole and equip yourself with the proper PPE.

In case you want to punch huge, perfectly round holes in materials including wood, drywall, plastic, metal, and so forth., you need a hole saw! Moretop stocks many brands of hollow saws and hole saw kits that you can purchase today.

Moretop is a Professional China Manufacturer and Supplier of hole saw arbor, We Provide Custom Wholeslae hole saw arbor factory, Private Label hole saw arbor and hole saw arbor Contract Manufacturing, Contact us now to get the best quotation for hole saw arbor, We will respond in a timely manner, we are not the lowest price of hole saw arbor, but we will provide you with better service.

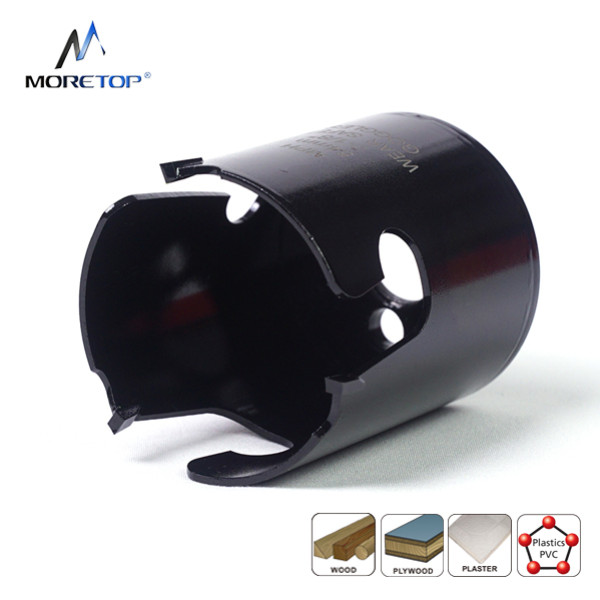

MORETOP Massive tooth design TCT multi-purpose hole saw

MORETOP Massive tooth design TCT multi-purpose hole saw